I've long wanted to learn more about the mysterious arts that go into the glassing of surfboard.

So I signed up for the one day 'learn to glass a surfboard' course with the boys at The Surfboard Studio in Melboune.

The notes below are a record of my stoke that I'm keen to share.

They are for my own future reference and I welcome any comments, inputs , how to improve or additional tricks of the trade.

I finished and and painted a blank with a quote from Gerry Lopez - "Let life be an anti- contest."

Fern embroidered it on her Mr Pipeline Aloha to Zen cushions and the message really strikes a chord with me.

I packed it up and brought and brought it with me on the plane (what! you took an finished blank on the plane!).

Zak from The Surfboard Studio has a fantastic set up.

Tyler and Kent were great hosts and skilled and patient teachers.

Zak has quite a serious vintage collection stashed in the rafters that kept me drooling all day.

The first thing Kent and I did was have a look at my blank under the lights. We saw the stringer was a bit high because I'm always nervous planing the string as I always seem to put long gouges in the foam.

The first trick I learned was to sand off the corners of the blade on the stringer planer to stop it digging in.

Then I learnt about using futures fin jig template.

And the leg rope plug

The next trick Kent taught me is to keep a really old piece of gause till its really soft and cut it into a strip. This is a good way to do the final finish on the rail.

And to take fine gause and a soft piece of foam and remove the scratches with digging in and creating flat spots.

Then Tyler made up some resin, added catalyst and that filler thats not Q-cell?? but a nasty asbestos like substance that helps make the resin thick like peanut butter.

Fill just the bottom

Place fin boxes with dummy fins and push down till peanut butter resin comes through.

Clean up and fill gaps with a cut down squeegee.

Don't forget to tape off fin boxes

and leg rope plug

Pull out enough 4 oz for the bottom.

Keep the cloth straight and even, i.e. don't pull from the corners.

tug down on the 4 corners to get a nice snug fit

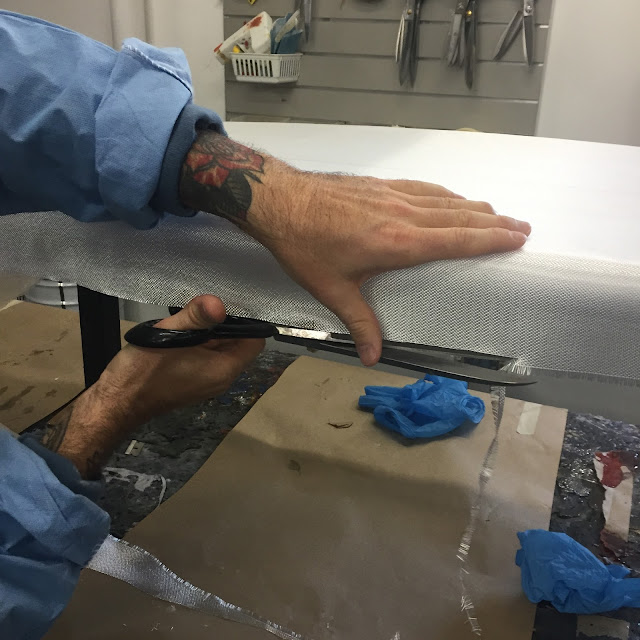

Cut the cloth with a nice sharp long bladed sciccor one thumb length evenly around the board.

A little tighter on the nose and tail.

A clean cut is a good cut and makes less work latter.

The next trick I learned was to cut in the nose like so.

When folded back will add extra strength the nose.

do similar cuts on the tail.

etra layers folded back adds extra strength

and flyers

roll the cloth back, don't fold it, to place decals

this will make sure the cloth flops back into correct position naturally

get your squeegees ready by cleaning them up in acetone

wet down your decals

let the cloth unroll

pour down half a boards worth of resin

work it into the cloth

working it out to the edge in a bead

use the bead to fully wet the lap

work the resin out so its not too wet but the cloth isn't showing. If the cloth is showing add more resin and do again.

fold the lap under.

all the way

the next trick is to pull back and cut off any dags and loose fibres

cut a triangle of off cut glass and reinforce the swallow tail

work glass into flyers

fill bubbles with resin by hand

bake it in the sun or oven. 4 mins then rotate then 4 more mins

flip board and paint a bead of resin over the lap and onto the resin to protect it during sanding.

bake it and then sand the lap and bead

clean up excess glass

all the way around.

Now to glass the deck. Lay the 6 oz cloth. Run your finger over to find drips or bumps missed by eye, sand 'em off.

cut the 6 oz on the rail

do this by using the scissors to almost cut into the rail

Next time I'll cut arches in on the nose to give that lovely shadow effect.

do the next layer of 4 oz straight over the 6 oz cloth

Cut 4 oz cloth at thumb distance.

Pour resin.

Work onto laps.

Fold lap.

Bake.

during the bake the cloth settles and resin moves so find the bubbles and cut them open with razor blade

Open just the top of bubbles so they will fill with resin.

Add cloth patches over fin boxes.

Tape up tail to create a dam.

Damn damn damn.

Paint bead on bottom lap.

Wet in fin box patch.

Fill dam.

Bake.

Bake.

Remove tape.

Sand lap.

That stuff will clog sander so change disc as necessary.

Clean up dammed area on tail by hand.

Make up a batch of sanding resin, 1.5 liters, by adding 5% wax and styrene.

This will make the resin harder and easier to sand and won't clog sander.

Add filler coat.

Use soft brush.

Moon shaped strokes one way up board pushing excess resin to the edge.

Moon shaded strokes up the other way.

Criss cross stokes up the rail.

Finish with long even stoked nose to tail working excess resin to edge.

Continually wipe excess resin off the brush

Then finish the rail with long strokes, picking up drips.

Bake.

Flip.

Repeat on deck.

Sand down fin boxes and rough areas on tail.

Remove tape.

Sand the board at a slow speed in long slow even sanding motion.

Watch out for areas on the nose and tail and rails and high points that you don't go to deep and expose cloth.

Finish rails by hand, looking to smooth out an shiny low points caused by brush strokes.

If you want to do a finer finish coat continue on from here.

Tape up the rails just on the wide point to create a skirt.

Don't forget to re-tape leg rope pug and fin boxes.

Paint on another layer of sanding coat resin.

Tap it underneath to get bubbles of wax to settle and brush marks to smooth out.

Paint it on.

Bake it.

Tape it- overlap about 1mm.

Do the bottom.

Sand it with finer and finer grades.

Watch your angle, not to deep to create screeches, not to flat but enough to remove material.

Remove the lip on the rail with razor blade.

Hand finish with used discs.

Hand sand with wet and dry, 600 to 800.

Use orbital at 1200.

Squegee.

Finished!

Thanks for that. It's the most informative story I've come across so far to explain glassing a board. I shape and do repair glassing but haven't tried a whole board. After seeing this I'd like to do the course too.

ReplyDelete